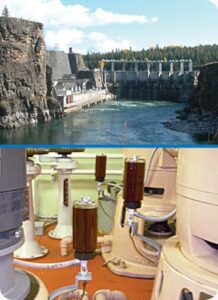

This hydroelectric dam utilizes Oil-Rite lubricators. The customer initially purchased oilers from a different company and experienced recurring leaks. The supplier’s replacement parts were complex to install, not easily obtained, and did not offer a permanent solution to the problem.

A purchasing agent worked with one of Oil-Rite’s technical sales representatives to determine the kind of lubricator best suited to the application. Single feed electro lubricators were selected.

Lubrication occurs when the solenoid is activated, making the unit especially suitable for intermittent operations. The specific model chosen features a durable and economical 1 quart,

polycarbonate reservoir. The clear reservoir allows for easy liquid level viewing. The reservoir and sight are vented to allow liquid to flow by gravity. An adjustable precision needle valve is provided to control the flow rate; it has a friction lock to guard against loosening from vibration. Drop feeding is observed through the glass viewing window in the valve body. The unit features a threaded shank for mounting to a bracket. This photo shows Oil-Rite lubricators installed on the hydroelectric dam’s primary pumps for water-power generation.

Since purchasing lubricators from Oil-Rite, the customer has had no costly reservoir leaks and is very satisfied with the performance of the lubrication equipment.

Oil-Rite offers an extensive variety of gravity lubricators, suitable to a wide range of applications. Click here to view detailed product descriptions and photos of each item in the online product catalog.