01 / 05

02/05

03/05

±1/4"

Liquid Level Gages with Adjustable Centerlines accommodate centerline distances up to 1/4″ longer or shorter than the specified measurement, for total adjustability of 1/2″.

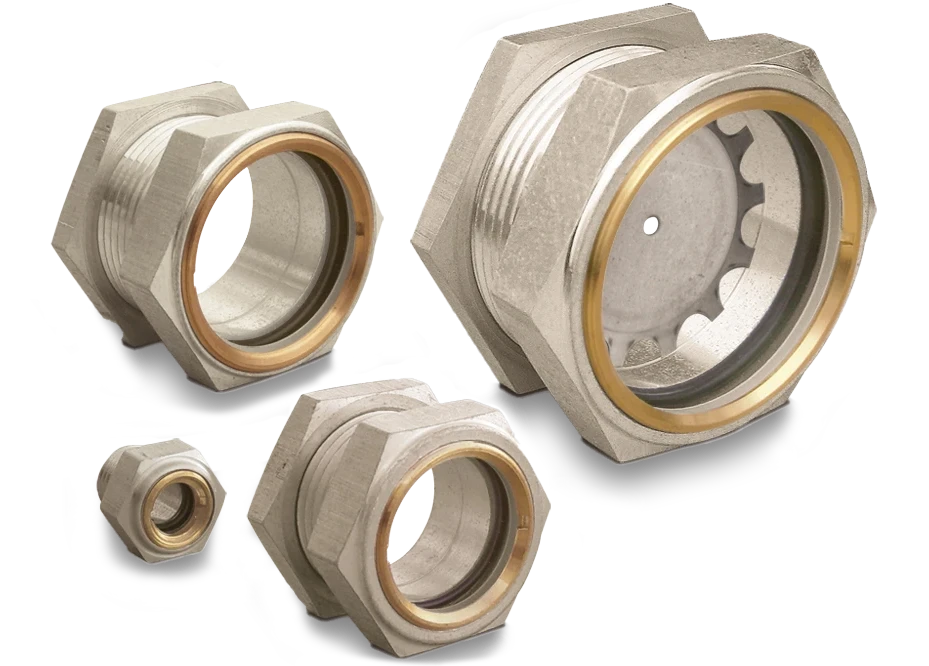

Universal (Bulls-Eye) Sight Feed Valves allow visual observation of the liquid stream from a distance, with the volume of flow controlled by an adjustable needle valve. Bulls-eye sight feed valves have excellent flow characteristics with low pressure drop.

04/05

Capabilities

Metal Cutting

Lubrication equipment must stand up to tough environments where dirt, heat, and vibration are common. The ideal component material is selected from steel, aluminum, brass, or stainless steel, then turned, drilled, threaded, and milled on CNC machinery. These operations are not outsourced or imported, but rather done on site utilizing skilled machinists.

Seal Integrity

Seals are critical to the function of lubrication equipment. A leak is messy, unsafe, and can contaminate product and the environment. Proprietary sealing methods are part of every purposeful Oil-Rite design. Connections, seals, and viewing ports of lubrication equipment are made to hold tight and be even more reliable than the machinery they serve. Not just made; Made to work.

Vertical Integration

95+%

of machined and molded components are manufactured in-house

R&D

on-site engineering and design

Built to Order

3,400+

stocked components for quick turnaround

Capacity

1 - 1M

short runs or long runs

05/05

In-House

The ability to make custom product to customers’ exact specifications has built demand for Oil-Rite’s manufacturing services beyond the scope of lubrication equipment. Oil-Rite applies its design and manufacturing expertise to machining and molding components:

CNC lathes, mills, and multi-spindle machinery enable turning, milling, burnishing, reaming, and drilling to tight tolerances. Blow molding, injection molding, robotic welding, and assembly work is also available on a contracted basis.

Resources

4325 Clipper Drive

Manitowoc, WI 54220

© Oil-Rite, LLC. All Rights Reserved. Privacy Policy | Terms of Service | Sitemap | Website Design by Lion Tree Group